Improvement of processes

Valladolid, where CARTIF is based, is one of the most fortunate regions in Spain because it is surrounded by extensive wine-producing areas with a great variety of grapes and some of the best Designations of Origin in Spain and the world. The river Duero, as the backbone of the vineyards, also cuts through other nearby provinces. That is why Castile and León has no less than 9 Designations of Origin that comprise almost 600 wineries.

The wine sector in Castile and León represents 6.6% of total sales in the regional agro-food industry, which means that with 582 million euros (latest published figures from 2012) it occupies fifth place. With 596 companies, it is positioned as the third largest sector in the Castile and León agro-food industry. The land area of vineyards in Castile and León at the end of 2013 was around 75,000 hectares, the fourth largest in Spain. We should emphasise that, of this land area, over 65,000 hectares belong to Protected Designations of Origin (PDOs).

since its beginnings CARTIF has worked in the wine industry from various perspectives

These figures are important but, even more significant is the Autonomous Community’s commitment to quality vineyards. In the last 15 years the area of vineyards ranked as quality vineyards has increased from 38% to 87.35%*. With this potential, it is no surprise that since its beginnings CARTIF has worked in the wine industry from various perspectives.

A comprehensive overview

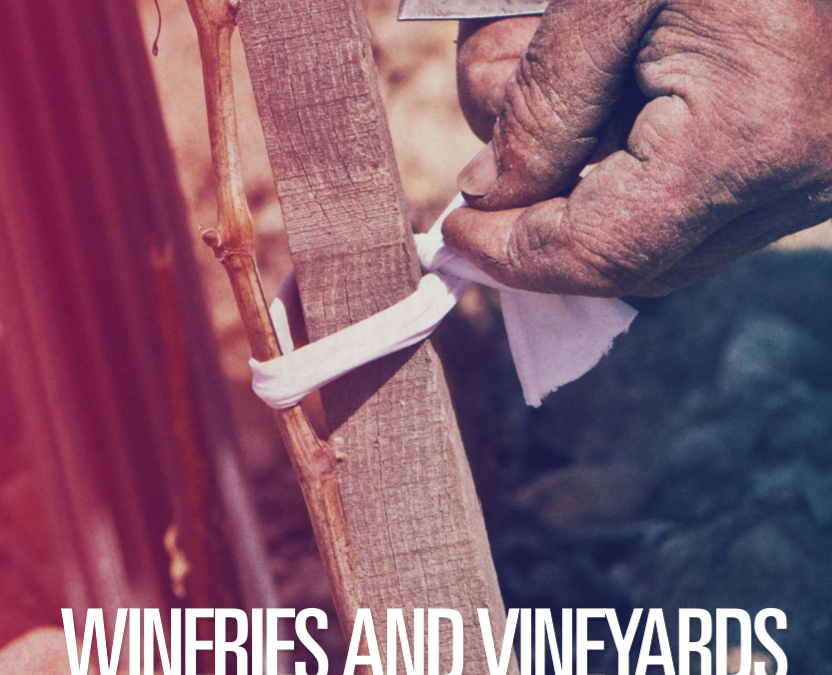

Wine, considered as an end product, is just a small part of a laborious process that begins in the soil. In fact, there is a certain amount of confusion in Spain when speaking about the name of the sector, using the words viniculture and viticulture indiscriminately. Regarding the etymology, the viticulture sector is that which covers grape growers, while viniculture covers wine producers. We can therefore understand that wine making unites both sectors and this is the public objective of the technologies developed at CARTIF.

The centre provides solutions to very specific challenges that arise from the soil to the bottle, to both growers and producers. At the Agroforestry Analysis Laboratory, agronomic and water analyses are carried out (using an in-house control tool), which make it possible to offer advice that is adapted to the needs of the farmer, thereby minimising risks and achieving the highest possible profitability.

One of the keys to the management of a crop is nutritional management and monitoring, assessing the specific needs of the plant and adjusting the irrigation and fertilizer levels. This management also entails the sustainability of the operation, by eliminating leachates (the contamination of aquifers and the disintegration of soil). This way the crop yield is improved and the environmental impact is minimised. This aspect is completed by specific solutions for the assessment (reuse) of effluents and waste, points that we will deal with in more detail later.

Another solution that CARTIF provides to producers is the possibility to design machinery for viticulture and wine bottling according to the client’s specifications, machinery that can be controlled and monitored through guided laser systems, GPS and GIS systems.

Improvement of processes

Once in the winery the Agro-food Biotechnology Laboratory studies how to apply new technologies to the production of fine wines, in order to facilitate the extraction of beneficial components (polyphenols) during fermentation and maceration, overcome the environmental and economic challenges posed by traditional filtration systems, and enable early detection through the RT-PCR (Real Time Polymerase Chain Reaction – 24-48 hours) technique of Brettanomyces yeasts that could lead to unpleasant smells or flavours in the wine. Improvements in the preparation process are completed by the quality control of raw materials and the finished product, using physical/chemical, microbiological and sensory techniques. Using advanced visual inspection techniques at the filling stage, colouring of the wine, reading the labels, checking the correct placement of corks, lids etc., improves the quality of the wine and its brand image.

Efficient waste management also provides additional resources for the company itself

The process can be optimised even further by using the antioxidants, polyphenols and other natural products with high added value obtained from the grape marc, which can be used as additives in the food, cosmetics and pharmaceutical industry. Efficient waste management also provides additional resources for the company itself.

One of our most sought-after services is the identification of autochthonous yeast groups involved in the wine-making process through molecular techniques. These yeasts, which are responsible for fermentation, are specific to each winery and influence the physical/ chemical characteristics of the wine. When using dry active yeasts for wine fermentation, these molecular techniques can be used to carry out an inspection on the addition of the dry active yeasts in the process, checking if they are the yeasts that drive fermentation or if they have been replaced by autochthonous yeasts.

Improvements in management

CARTIF researchers have developed an optimisation and control system for wine production that enables the comprehensive management of the process. Starting with a determination of the optimum time for the grape harvest and providing a forecast of the development of diseases in the grape (including an alert service), the SAGIT makes it possible to automate traceability from the vineyard to the end consumer. Its benefits include the ability to manage the origin (supplier orders, conditions), the operations performed (date/ time, conditions), the efficient management of stocks and resources, the management of orders, assignment of batch numbers, etc., and guarantee consumer safety.

Energy recovery from waste entails the quantification and classification of waste such as the vine shoots obtained in the pruning of vineyards, grape stalks or other lignocellulose waste products such as unused pallets and barrels, which can be used as fuel for biomass boilers. The advantages of efficient energy management in facilities include a reduction in energy costs, which could represent a major economic saving for companies, as well as eliminating the need to manage waste traditionally, with the resulting reduction in costs for the company.

Considering sustainable development criteria in the management of a company will also have a considerable impact on the company’s image.

Improved energy efficiency solutions can also be implemented in order to improve sustainable development, ranging from the integration of renewable energies to the recovery of residual heat from the fermentation process and integrated energy optimisation that encompasses all processes and makes them energy efficient, with the corresponding saving in costs.

A sustainable winery, excellent quality wine, fast, modern processes and a considerable saving in costs are all possible through the application of the right technology.